The realization of the overall concept – mechanical assembly is the last link in our production chain. We carry you off to our WMS assembly halls.

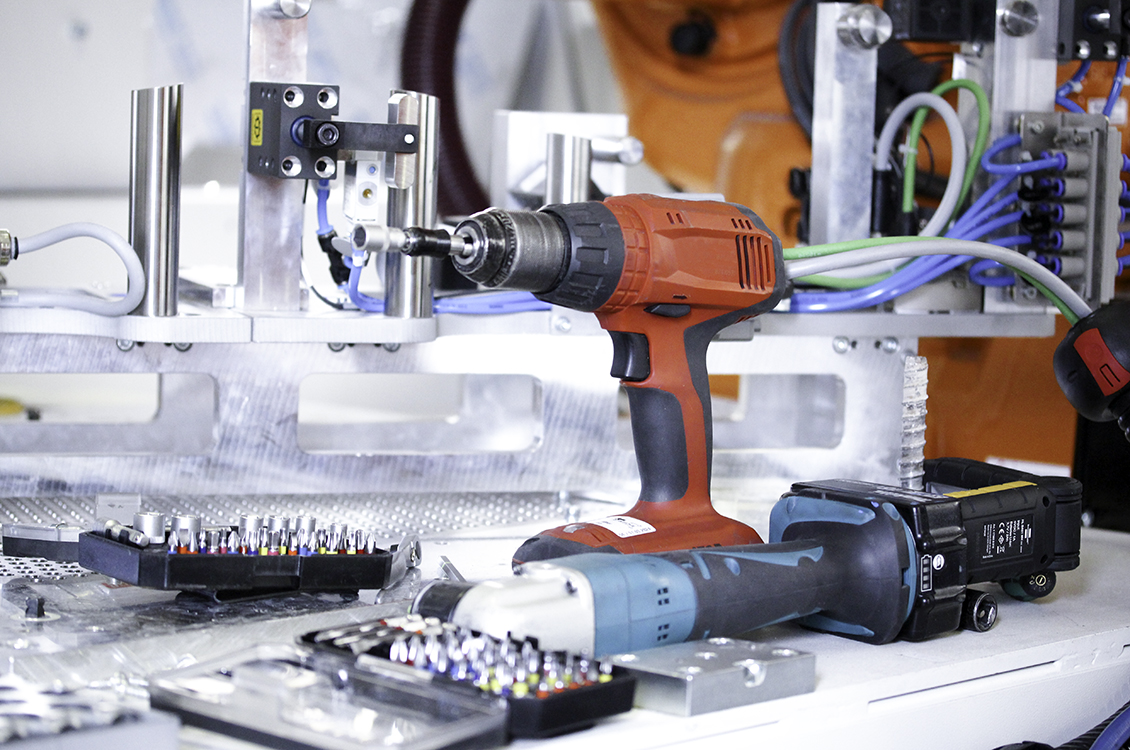

Little by little. Based on the prefabricated cell frame, the individual components are assembled by our technicians. The steel structure is clad with perfectly matching metal sheets. These parts are manufactured by established and reliable suppliers on our behalf. Through the integration of the individual components, the interior of the machine is gradually assembled.

After the modules have been arranged and fastened according to plan, the work of the system electronics engineers follows.

The big picture. Once all components have been assembled and the programming has been completed, the preliminary acceptance is carried out by the customer. This includes an inspection of the machine as well as a trial run. If all requirements have been fulfilled and a smooth process is guaranteed, the delivery can be notified.

Time to say goodbye. Time to send our machine to its destination. The packed machine is loaded and shipped to the customer. There it can be unloaded from the truck and taken to its place of use by forklift or crane.

Anyplace, anywhere, anytime. Beyond our WMS assembly halls, our technical assemblies are also on site at the customer’s premises to install the new system. This way, we guarantee optimal commissioning and sustained success.