A picture says more than a thousand words. That’s why we have prepared some images and videos for you. Allow our products to convince you. We will also gladly visit you for a consultation. Just make an appointment with our sales team.

Tools

You can find additional information on tools on the tools page

Completed projects

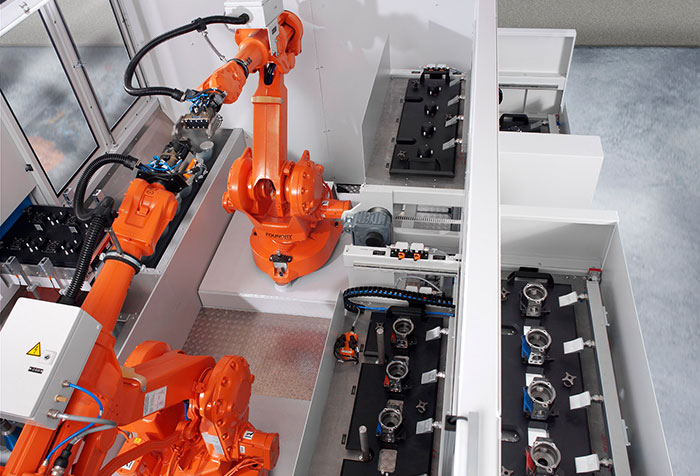

Handling cell for round components of up to 30kg. Heavier components are possible.

Some of our satisfied customers are already operating different configurations of this TWIN cell with 2 collaborating robots 24/7. Components with weights up to 10kg are removed from a conveyor, deburred and discharged. Independent of the feeding and removal process, SPC and NiO parts can be discharged, e.g. via a slide.

For our apprentices, interns and students, we have commissioned the production of an in-house training cell as part of a bachelor thesis. This work of a graduate is supposed to allow other graduates to gain some first-hand experience with robotics. Thanks to its compact design, this WMS cell can be made available to schools and universities. It is an in investment in the future from WMS and the next generation of skilled workers.

This TWIN cell for handling and deburring piston pump housings has been in operation since 2008. In this configuration, a „drawer system“ is responsible for loading and unloading the cell. One „support“ is loaded and unloaded while another „support“ is handled in the cell by the robot. As soon as the parts have been machined and put down by the robot, the upper and lower trays are switched automatically.

DETAILS / WMS-INSIGHT

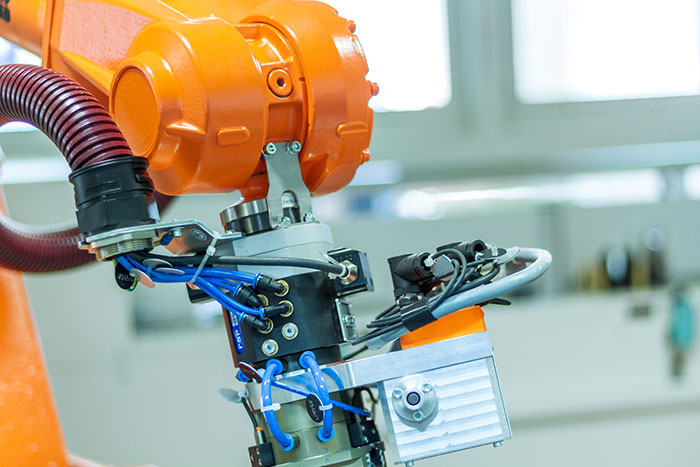

The product design also includes the design of the gripper. Together with our partner Schunk, we can reliably and effortlessly implement nearly any requirement.

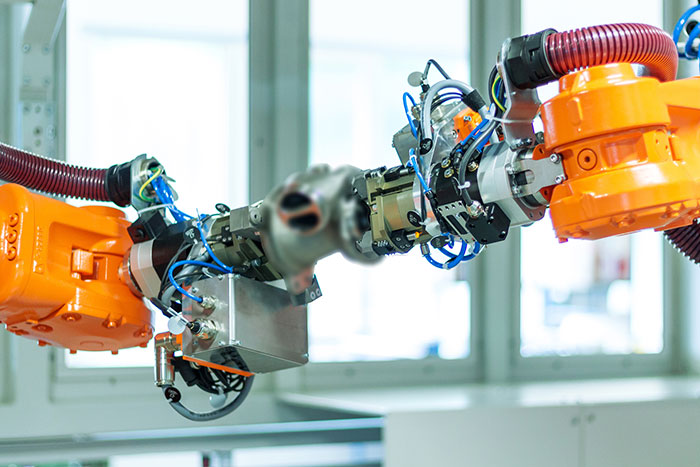

Our robot programmers are at their best when faced with complicated challenges. To them, transferring a component from one robot to the next is almost child’s play.

Videos

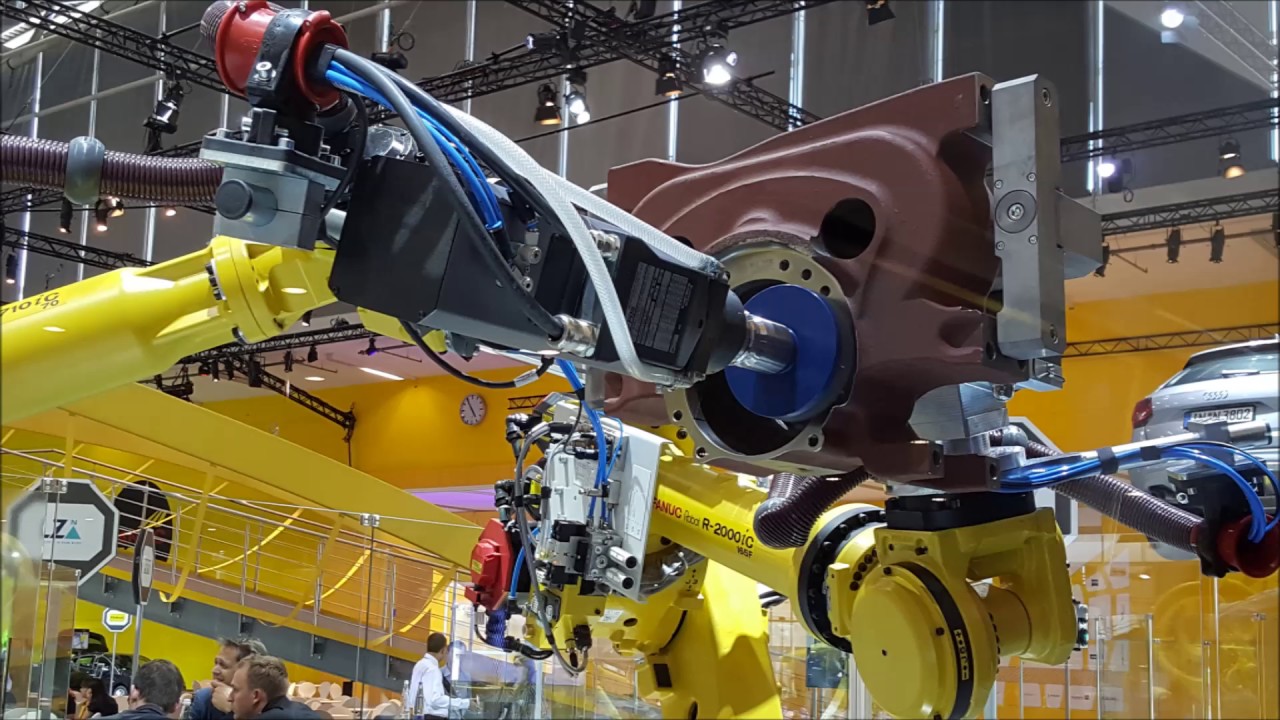

At trade fairs, on-site at the companies of our customers or in-house at WMS – our employees bring to life the many individual parts and assemblies in many locations and, using our more than 20 years of experience, transform them into what we do best: fully automated robot cells. See for yourself: